Everything To Know About Waste Tyre Pyrolysis Plant Project

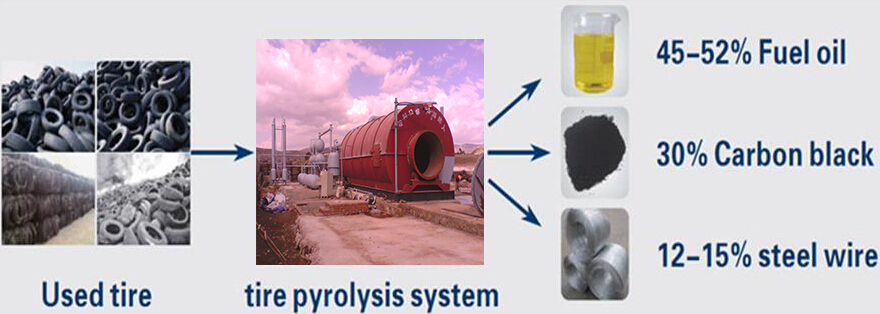

Waste tyres are one of the most significant forms of air pollution in the world today. Many people have been observed to just burn these waste tyres out in the open without any consideration for the environment. The lack of waste tyre recycling plants is the main contributor to this alarming phenomenon. Waste tyre pyrolysis plant was invented for this sole reason of helping people to recycle waste tyres. Here to know waste tyre pyrolysis plant cost.

Some years back, pyrolysis plant manufacturers were very limited but now there are several companies that offer services in form of manufacturing, setup and installation of tyre recycling plants.

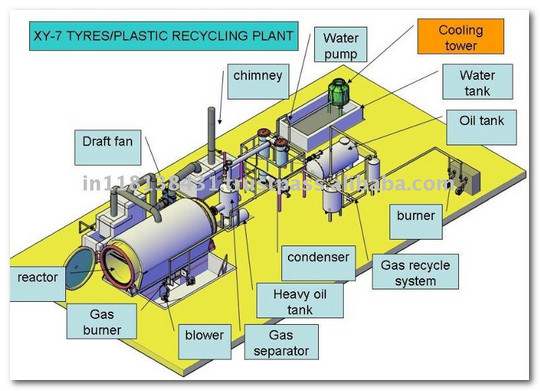

When it comes to setting up a waste tyre oil plant project report then you cannot compromise on quality of equipment as cheap equipment will not serve the purpose as desired. Make it your job to find out the few equipment manufacturing companies that have a good track record and a good reputation in the tyre recycling industry. Take your time to research and find the best equipment for your proposed tyre recycling plant.

This article can give you a fair bit of idea about the steps you need to take before make your decision. To start with, you need to identify what equipment you need and what are the specifications of those equipment. For these, you should first consult an expert who you can sit with and find a thorough understanding of what the equipment specifications are. Once you have a fair understanding of what it is that you need, then you should start looking for suppliers online. Go through all the information that is available on the World Wide Web. In fact, you could choose to look at similar websites too in a bid to understand which company is offering you the best price for the equipment that you need.

Once you have a fair understanding of what it is that you need, then you should start looking for suppliers online. Go through all the information that is available on the World Wide Web. In fact, you could choose to look at similar websites too in a bid to understand which company is offering you the best price for the equipment that you need.

However, it is not on price alone that you should make your pick. This is primarily large equipment that is in most cases expensive but you want to pick up something that can give you value for money. You need to identify suppliers that offer you service guarantees.

When you get a service guarantee you can sure that if anything were to happen to the equipment, you can get it serviced as and when needed without anything stopping your set up. Once you have a list of at least three or four suppliers, you should go ahead and call them or email them with regards to your requirements.

Once you receive some mails with quotes in your inbox, request our site expert to sit down with you and go through all the estimates carefully. Once you are absolutely sure about the company you want to place your order with, call them up and place the order and wait for the equipment to arrive at your doorstep.