When any organic material is subjected to very high temperatures in the absence of oxygen, a thermochemical decomposition of the material takes place, in a process called pyrolysis: https://www.bestongroup.com/pyrolysis-plant-for-sale/. This change occurs both in the chemical composition and physical state and cannot be reversed. The separation occurs because of the high heat and fire.

Vehicle tyres are constantly under wear and tear because of the rubbing against pavements at high speeds and this causes a deterioration in their treads, which renders them unusable. Tyres can also be rendered unusable when they get punctured or damaged otherwise. The very high incidence of vehicular traffic in the modern world has led to more than 300 million tyres being rendered unusable and having to be discarded, annually. Tyres contain a lot of components that also make them unsafe for disposal in landfills, and the waste tires recycling machines have made it possible to recycle the discarded tyres, so that the material in the tyre is converted to something useful. It is also quite common to burn waste tyres for their fuel value.

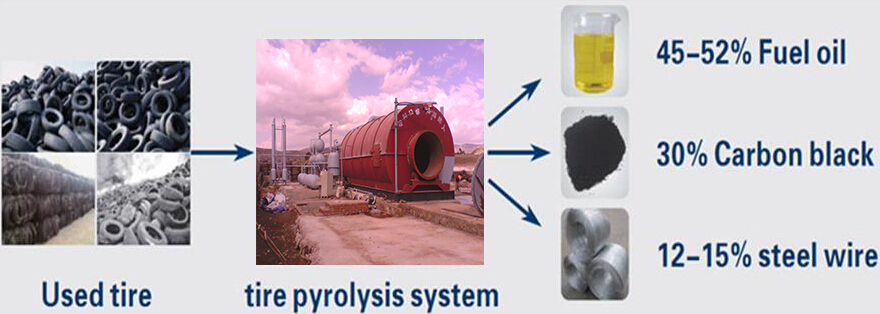

In this pyrolysis method, the tires are first shredded and put into reactors, which can be sealed off from the atmosphere, so that there is no oxygen in them. The heat in the reactors, first soften the rubber and the polymers in the rubber breakdown into small molecules, which vaporize. These vapors can either be burnt to produce power or condensed into a liquid, which has oily properties and can be burnt. Minerals in the tyres make for forty percent of the weight of the tire and can be retrieved as a solid. Pyrolysis is a very clean process where there is no waste or other emissions. Get more tyre pyrolysis plant manufacturers China here.

Tyres contain fibers and steel, which can be removed during the shredded process, or removed from the output of the process by using magnets. The other remaining solid material has no value, though technology has been developed which can recover carbon black products that can be used as supplements in the rubber and plastics industries. Waste tyres that have gone through their useful life still have a lot of energy left in them from the chemically binding that the manufacturing process puts them through. The waste tyre recycling machine allows the retrieval of high energy gas, steel, char and hydrocarbon oils. The ratios of these products depend on the conditions used in the process and the high temperatures the waste tyres are subjected to, during tire pyrolysis. The high energy gas is often used as a source of energy for the process of pyrolysis while the char and steel are retrieved for recycling and the oil produced by the pyrolysis can be mixed with diesel and used as a fuel.

Pyrolysis is not the only method for using waste tyres, and these discarded tyres are used in a lot of civil engineering applications. They can be used to create very firm, though temporary retaining walls, when filled with earth. Tyres can also be used to create retreaded tyres, while ground rubber can be used to produce rubberized asphalt, which has excellent properties for floors. Learn about the tire to fuel plant.