With the constant increase in rubber tyre waste, a viable, sustainable solution needed to be created. The pyrolysis plant in India is that solution. Pyrolysis plants help to transform a proportion of the 65 million scrap tyres produced throughout India annually, into fuel that can be used in industry for producing electricity, heat and steam.

Pyrolysis plants extract carbon black power and tyre oil (also known as Pyrolysis oil) which is then processed and transformed into usable fuel. The pyrolysis plant in India thrives because of the easy access to the raw material they need.

The Pyrolysis plant, also known as a “plastic and tire recycling unit”, “tire to fuel industry” and “plastic to fuel industry” is categorized as a renewable energy project, or waste plastic and tire pollution control equipment. Since rubber doesn’t decompose easily, it’s known as “black contamination” and had become a serious threat to the environment.

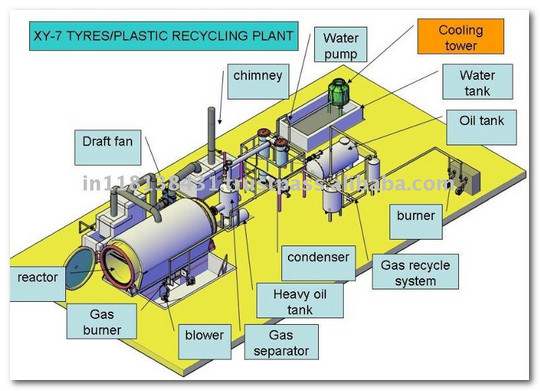

The process of a pyrolysis plant in India

The process starts with the raw materials of waste tires and plastic being fed into air-lock feeding and the pyrolysis is extracted. At this stage, the Pyrolysis is either processed into Carbon Black – in which case it goes through a cooling and bagging process, or it is transformed into oil vapour and gas.

The oil vapour and gas is then put through a fractional condensation process, which produces heavy oil and carbon sludge (which is then returned to pyrolysis), pyrolysis oil, which is then put through a clarification and stabilization process and stored underground as fuel oil, or Hydrocarbon gas, which undergoes storage and firing, transforming into Flue gases. These Flue gases are then processed through energy recovery for combustion air and drying, and scrubbing, which produces clean emission. This process uses the whole of the tire, with no material remaining, meaning scrap is used and no further scrap created.

According to research, petroleum worldwide will be depleted within the next 15 years, which means we have to come up with a more sustainable way to create fuel. The waste tyre pyrolysis plant certainly seem to have achieved this. The output of tires in India alone is now over 1.3 billion, and the scrap volume is increasing year on year. The combination of the increase of the black contamination of tires, along with the fact decrease in petroleum fuel means that the pyrolysis plant in India provides a valid, sustainable solution to a serious worldwide problem.

The easy availability of the raw materials needed, combined with the high demand for the finished product makes the tyre recycling plants an extremely profitable business, often producing a return on investment within a year.